1. Introduction

Pickering emulsions stabilized by plant derived particles align with clean

label demands yet faba bean protein isolate (FBPI) often shows limited

interfacial performance due to low solubility and compact globular

structure. Non covalent interactions with polyphenols can modulate protein

conformation but the cooperative effects of dual polyphenols remain

insufficiently understood. This study aimed to enhance Pickering emulsion

stability by forming FBPI complex nanoparticles with gallic acid (GA) as a

small phenolic acid and rutin (RU) as a bulky flavonoid glycoside. The

objective was to clarify how the complementary molecular characteristics of

GA and RU generate cooperative structural and functional modulation of FBPI,

thereby reshaping its molecular conformation, particle level properties, and

interfacial assembly within a moderately unstable emulsion system with an

oil volume fraction of 0.6.

2. Materials and Methods

Pretreated FBPI was mixed with GA at a fixed concentration followed by RU

addition at increasing RU to GA ratios (0.0:1.0 ~ 1.0:1.0). Non covalent

FBPI-RU/GA complex nanoparticles were characterized for particle size,

ζ-potential, polyphenol binding content, solubility, exposed sulfhydryl (SH)

and amino residues, and secondary structure. Pickering emulsions were

prepared using canola oil and analyzed for droplet size (D4,3),

ζ-potential, interfacial protein adsorption, Turbiscan stability index

(TSI), and microscopic features. Statistical differences were determined by

analysis of variance with Duncan test at p < 0.05.

3. Results and Discussion

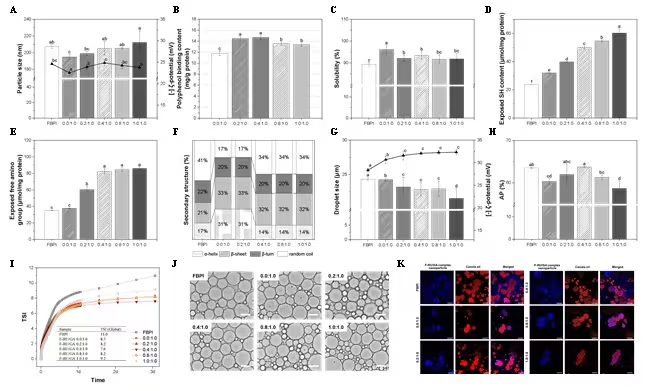

GA reduced FBPI particle size (Fig. 1A), increased solubility (Fig. 1C), and

transformed disordered secondary structures into more ordered α-helix and

β-sheet forms (Fig. 1F), improving dispersion and interfacial affinity.

Incorporation of RU progressively increased polyphenol binding (Fig. 1B) and

exposure of functional residues (Fig. 1D-E) while altering the balance

between compaction and unfolding. At an intermediate RU to GA ratio of 0.4

to 1.0, nanoparticles exhibited high solubility, more negative surface

charge, and a compact yet flexible secondary structure. These features

enabled efficient migration to the oil water interface and formation of

dense particulate films. The resulting emulsions showed smaller D4,3,

higher magnitude of ζ-potential (Fig. 1G), continuous fluorescent

interfacial rings in microscopy (Fig. 1K), and the lowest TSI (Fig. 1I),

reflecting strong resistance to coalescence and creaming. When RU proportion

exceeded the optimal level, over unfolding and steric congestion occurred,

reducing effective interfacial packing and weakening the particulate film.

These effects were evident in larger D4,3, decreased interfacial

protein concentration, and increased TSI values. Collectively these findings

indicate that Pickering stabilization depends on achieving an optimal

balance in FBPI structure where GA driven compaction and RU driven unfolding

act cooperatively rather than independently.

4. Conclusion

Dual polyphenol complexation offers a tunable route to engineer FBPI for

clean label Pickering emulsions. A GA RU ratio of 0.4 to 1.0 produced

nanoparticles forming cohesive and elastic interfacial films that markedly

enhanced stability, whereas excessive RU impaired assembly. This work

clarifies how dual polyphenols modulate FBPI and provides a design framework

for next generation plant-based stabilizers.

Fig. 1. Particle size and ζ-potential (A), polyphenol binding content (B), solubility (C), exposed SH group (D), exposed free amino group (E), and secondary structure of FBPI-RU/GA complex nanoparticle; droplet size and ζ-potential (G), adsorbed protein at the interface (H), Turbiscan stability index (I), optical microscopy images (J), and CLSM images of Pickering emulsions stabilized by FBPI-RU/GA complex nanoparticle. Scale bar=20 μm.

Fig. 1. Particle size and ζ-potential (A), polyphenol binding content (B), solubility (C), exposed SH group (D), exposed free amino group (E), and secondary structure of FBPI-RU/GA complex nanoparticle; droplet size and ζ-potential (G), adsorbed protein at the interface (H), Turbiscan stability index (I), optical microscopy images (J), and CLSM images of Pickering emulsions stabilized by FBPI-RU/GA complex nanoparticle. Scale bar=20 μm.