1144Structural Characteristics and Temperature-Responsive Sequential Release Behavior of Dual-Encapsulated Flavor Oil–Seasoning Biopolymer Complexes

1Research Group of Food Processing, Korea Food Research Institute, Wanju, 55365, Republic of Korea

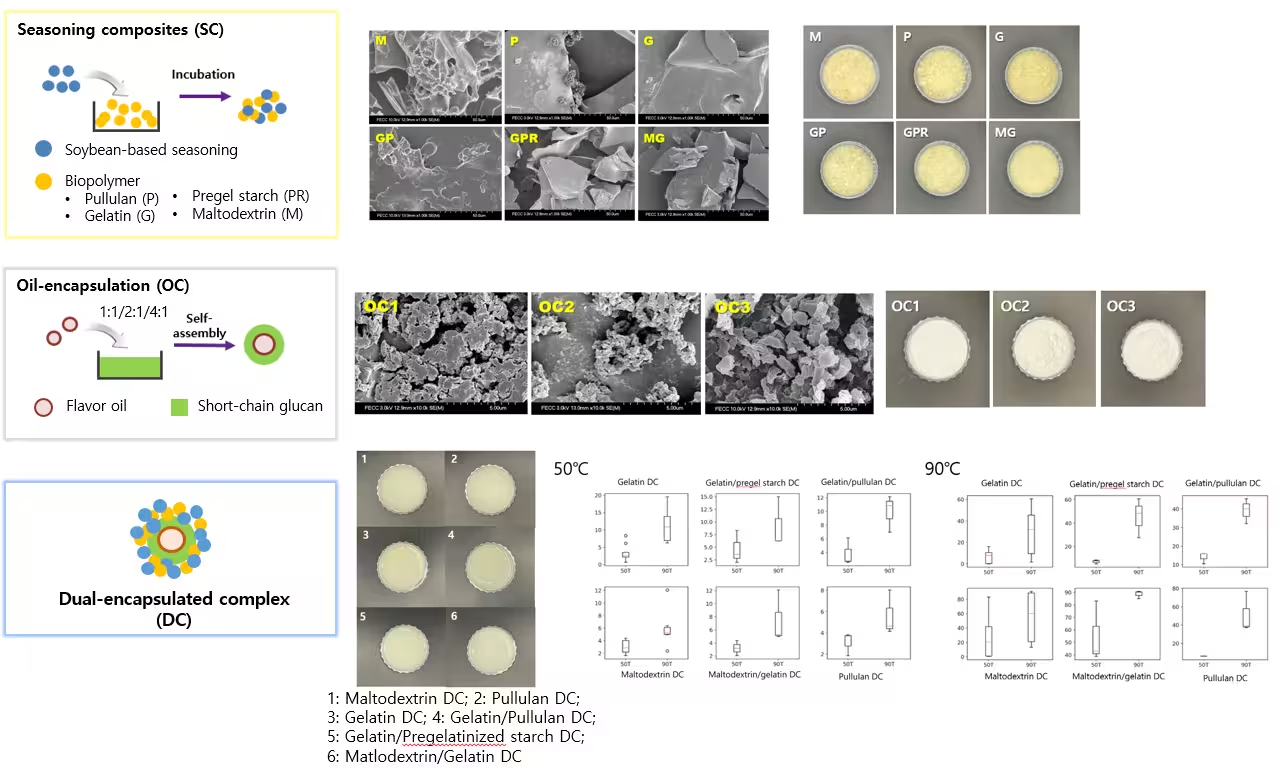

This study aimed to develop a novel biopolymer-based complex capable of dual encapsulation and temperature-responsive sequential release of flavor oils and seasoning components for food formulation applications. Hydrophilic biopolymers—pullulan, gelatin, pregelatinized starch, and maltodextrin—were used to formulate composites carrying soybean-based seasoning components (seasoning composites, SC). Separately, hydrophobic flavor oils were encapsulated using self-assembled short-chain glucan (oil-encapsulation composites, OC) and subsequently integrated with the hydrophilic matrices to form dual-encapsulated complexes (DC). Physicochemical properties, including appearance, structural features, and morphology, were characterized, and release behavior was evaluated at 50 and 90℃ using GC–MS to determine temperature-responsive and sequential release performance. SEM analysis revealed that each SC exhibited distinct microstructural characteristics depending on interactions among the constituent biopolymers. The maltodextrin SC displayed a smooth and dense surface, likely due to rapid solidification and pore formation during freeze-drying, whereas the pullulan SC showed a compact yet flexible network with partial particle aggregation. In contrast, the gelatin SC and gelatin/pullulan SC exhibited irregular and porous structures, attributable to protein–polysaccharide interactions that promoted cross-linking and pore development during drying. The OC, prepared by incorporating flavor oils with varying ratios of starch-derived ingredients, also exhibited pronounced morphological differences. The 1:1 formulation exhibited a relatively smooth surface attributable to excess oil loading, whereas increasing the proportion of starch-derived materials produced rougher surfaces with noticeable aggregated domains, suggesting that biopolymer content markedly affected oil dispersion and encapsulation efficiency. For temperature-responsive evaluation, core materials containing standard compounds were incorporated into the DC designed to disassemble at either ≥50℃ or ≥90℃, and fold changes relative to 30℃ were calculated. At 50℃, most formulations displayed significant increases in release, although the maltodextrin–oil DC exhibited unstable behavior, whereas the gelatin–oil and gelatin/pullulan–oil DC showed superior performance. At 90℃, release increased progressively, and formulations such as the gelatin/pregelatinized starch–oil, gelatin/pullulan–oil, gelatin–oil, and pullulan–oil DC met the intended design criteria by showing minimal changes at 50℃ but pronounced increases at 90℃. Overall, the developed dual-encapsulated flavor oil–seasoning biopolymer complexes represent a promising strategy for engineering smart seasoning systems capable of temperature-triggered and stepwise release of multiple functional components. These findings underscore the potential of biopolymer-based materials as clean-label platforms for the controlled delivery of flavor constituents in next-generation food processing and formulation.