a1101Physicochemical properties of dual modified rice flour by heat annealing and pressure annealing treatment

1Department of Food Science and Biotechnology, Kyung-Hee University, Yongin, Gyeon-gi, South Korea

Rice is a staple carbohydrate source widely consumed in Asian countries. However, its tendency to rapidly increase blood sugar levels has limited its broader application in food processing. Therefore, recent studies have focused on slowing digestion of rice, using physical modification methods. Heat-annealing treatment (HAT) and pressure-annealing treatment (PAT) have paid attention for their effectiveness in reducing starch digestibility and promoting health benefits. However, research on the combined effect of HAT and PAT remain limited. Therefore, effects of each modification method and its synergistic effect on the physicochemical properties of rice were investigated.

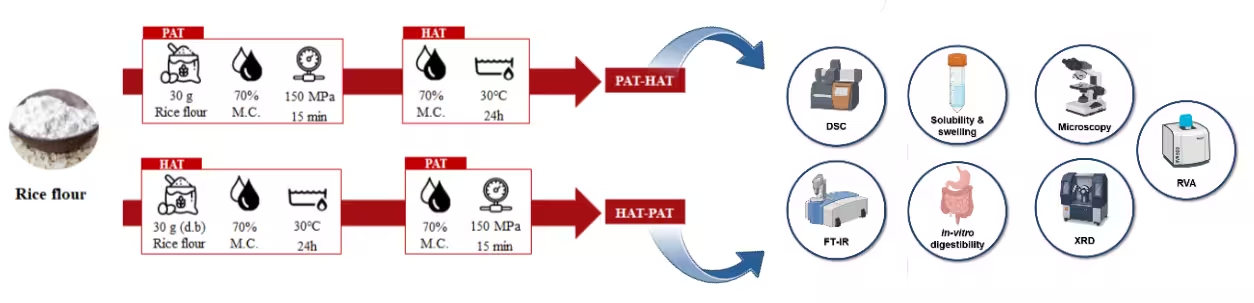

Rice flour was packed into PE pouches. The moisture content was adjusted to 70% by adding distilled water. PE pouches for HAT were annealed in a water bath at 30°C for 24 h, while those for PAT were treated with high pressure at 150 MPa for 15 min at room temperature. The rice flour suspension was then centrifuged at 2,232g for 15 min. HAT-PAT and PAT-HAT were treated under the same conditions with individual treatments, with only the sequence of treatment was altered. Physicochemical properties of rice flour were analyzed using morphology, FTIR, XRD, DSC, RVA, in-vitro digestibility.

Under uncooked conditions, none of the treatments increased RS content compared to native rice. However, after cooking, all samples showed a decrease in SDS and an increase in RS content. In the case of single treatments, PAT resulted in a greater increase in resistant starch (RS) than HAT. In the dual-treated samples, the HAT–PAT showed a higher RS content compared to PAT–HAT. In DSC thermal properties. HAT resulted in an increase in double helix melting enthalpy (ΔH), whereas PAT did not show a significant difference. All modified samples showed decreased ratios compared to native rice flour, indicating that short-range molecular order was partially disrupted. On the other hand, relative crystallinity (RC) increased with treatment. PAT, changes in the proportions of β-sheet and α-helix structures were observed. In RVA analysis, Peak viscosity did not show significant difference between native and modified samples. Breakdown viscosity significantly decreased in HAT, but not in PAT. Additionally, setback viscosity increased only in the PAT sample, suggesting a higher tendency for retrogradation during cooling despite the reduced stability during heating. However, when PAT was combined with HAT, it showed improved shear and heating stability, showing a reduced breakdown viscosity. In addition, setback viscosity was reduced in dual-modified samples, indicating that combining PAT with HAT altered its pasting properties. Morphological observations reveal altered aggregation and dispersion patterns of starch and protein, which influence starch-protein interactions and digestibility.

As a single treatment, HAT reduced the digestibility of rice flour by promoting the formation of double helices, thereby enhancing granular integrity and starch chain rearrangement. In contrast, PAT made the starch granules more compact and induced protein denaturation, which also led to a significant decrease in digestibility. When these two treatments were combined, the RS content reached the highest level among all samples by compensating for the limitations of each individual treatment.